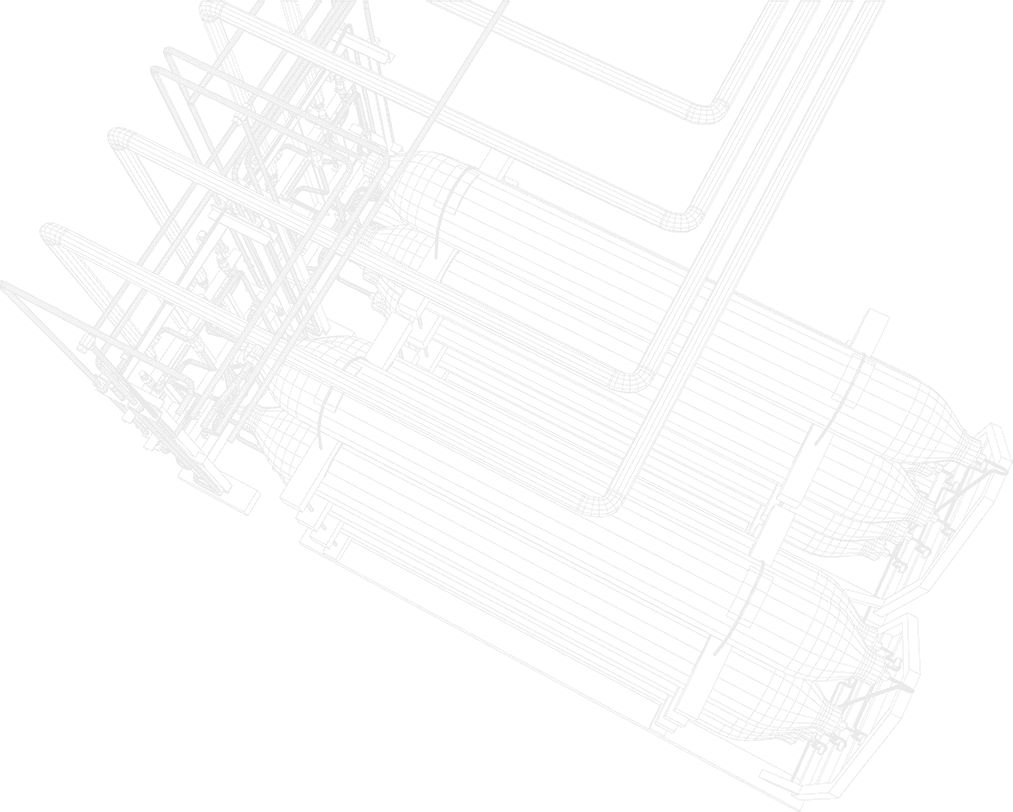

Being able to visualise the subsurface, for any application, is a major advantage. For the design and construction of oil and gas wells, this has been the missing piece of the jigsaw puzzle until very recently. Technology is currently allowing engineers to visualize wells that have been drilled using data, but the ability to designed the well virtually and then “simulated, inspected, reviewed, critiqued, modified, documented, drilled, completed and decommissioned” by a multidisciplinary team. The ability to drill a “digital twin” of the well bore before breaking ground is considered the “holy grail” for well design and construction – and only a few companies are in the race to achieve this

Oil & Gas – A Necessary evil?

It has become fashionable to demonise the oil and gas sector on humanities road to net zero – however those of us familiar with the facts understand that without hydrocarbons, the energy transition would be dead in the water. The fact remains that the planet is still using over 100 million barrels of oil a day, and this is set to increase over the next decade. With this, pressure continues to increase on the industry to reduce C02 and hit eventual net zero targets that are insisted upon by authorities (and popular demand). The only way to keep up production, to meet demand, is to do this more efficiently as the industry transitions.

The last drops..

Drilling and production is a high cost, high emission part of the oil and gas value chain. The paradox is that without it, the world would come to a standstill. So, the challenge is for the industry to drill and produce the necessary oil and gas needed as efficiently as possible. The only way to do this is through the use of the latest digital technology – allowing engineers to reduce risks and solve and potential problems before the mobilise rigs and spin bits.

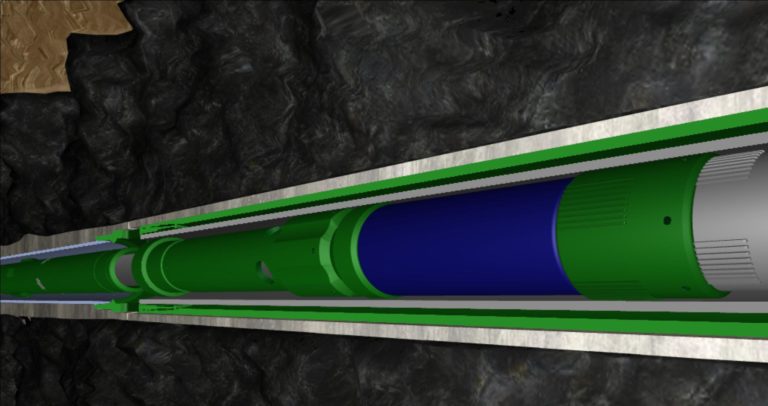

PetroCAD 3D (and 2D) visualisation technology is specifically designed to enable engineers to clearly understand the near wellbore environment and equipment installed within it. For the first time engineers can accurately design wells and perform virtual inspections to determine best approaches for intervening or decommissioning a well. We believe our technology will help reduce CO2 due to more robust well design leading to fewer mistakes out in the field safeguarding the environment.